Quality Assurance

From raw materials to finished products, we have a complete product inspection system to ensure the final product quality

Leading-Edge Manufactory

In China, we master the best sources of LED and drivers. And every equipment and process are in-house and leading in the industry. Therefore, we have full access to complete quality and cost control throughout the production. In other words, we are more capable of offering a reasonably good price for your project.

Our factory is welcoming global customers to visit and carry out face-to-face communication with us, so as to simplify your evaluation and maximize your efficiency profits. And we also invite you to know more about us from here

Visit Our Production

01. IQC

All material arrived in factory , not matter pcb , led , ic ,resistance ,aluminum profile ,cables, are need QC check . all the items need meet the requirement.

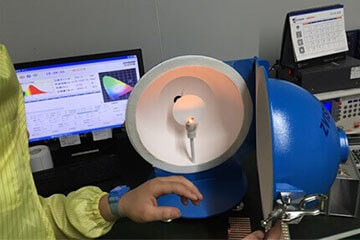

02. CCT Check

All led need test the color temperature ,we need to check the brightness , color temperature ,Color Rendering Index.We need to make sure client buy the products color the same as last order .

03. Dehumidification

All led need dehumidification before SMT.65℃*8hours .This ensure the led dry.

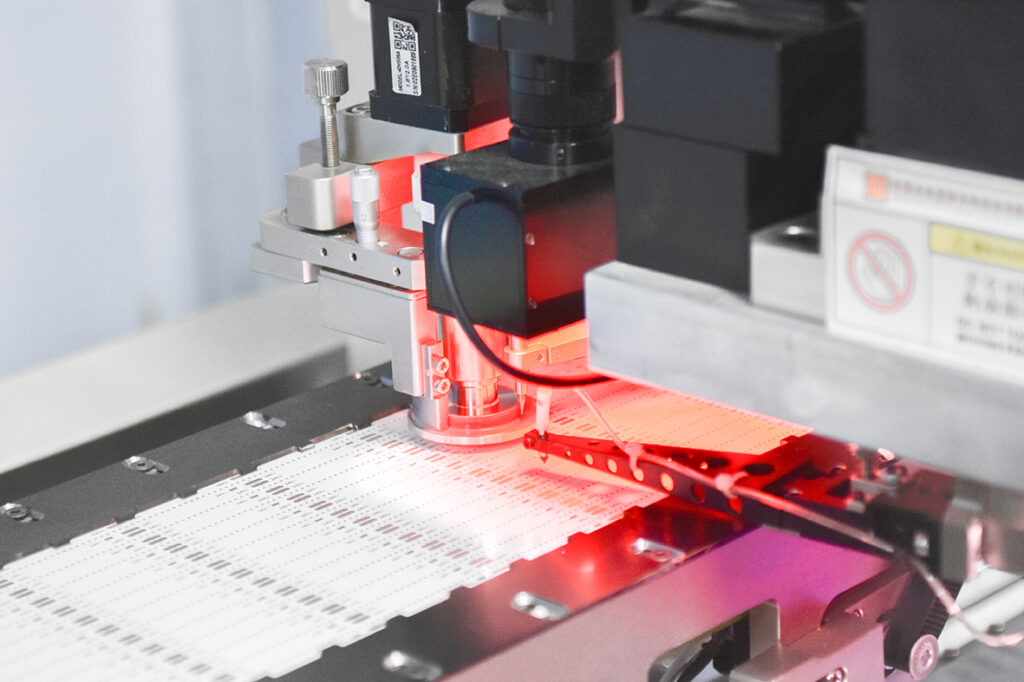

04. SMT Process

Producing LED ,IC,resistance onto the surface of the PCB. We are using the high speed automate machine . Ensure all the components are in the right place .

05. Reflow Soldering

After the SMT process , the led and PCB is join solder paste. This need go thought reflow soldering machine and in approx 220-250℃。 Then the solder paste thaw and bonding together.

06. Inspection

Our QC dept inspect 100% check of the strip light to ensure there are no defect LED and color shift LED.

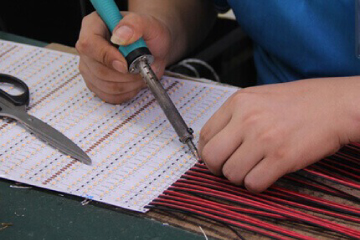

07. Soldering PCB

Our automate soldering machine will soldered the 0.5M pcb 10pcs to 5meter . According to customer request. Cable is soldering by hand. Machine soldering ensure the PCB soldering quality stabilized.

08. Clean PCB surface

Once soldering completed, the strip PCB will be cleaned by alcohol.

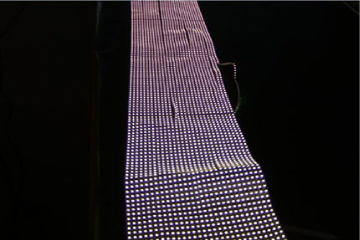

09. Ageing Test

All the led products need lighting test for 8 hours, ensure each LED runs in good condition. In this process , we can know weather led working well? Led in the right color temperature ? Driver working well ? This is very important.

10. Waterproof

IP55/65 (defend moisture) Silicon glue onto the surface of the PCB . IP65(defend raining) using silicon tube for the waterproof . IP67( short time using under water )using silicon glue injection into the silicon tube.

11. 3M Tape

All our led strip will be pasted with 9080A 3M tape, to ensure easy installation for end customer.

12. Final Quality Control

Our QC will check on every strip reel, to ensure consistent light color of the strip, as well as good appearance.

Sophisticated Manufacture Workshops

Drive Manufacture Workshop

Equipped with modern wave soldering, reflow welding, chip mounting, laser marking, foot cutting machines, and other equipment.

Automatic SMD Workshop

Imported automated surface mount technology equipment and toasters have fulfilled the complete functionality and capability of this workshop.

Product Assembly Workshop

That over 50 skilled workers, more than 3 well-developed product assembly and aging lines, are assuring eligibility and quality of the finished.

Multiple Versatile Showrooms

Up to 3,800m² of individual functional display rooms, presenting various samples of our complete commercial LED outdoor lighting series.

Factory Certifications